Imagine you were assembling a pizza on a touchscreen by dragging and dropping ingredients or moving them around with your fingers. Comparable to this, using automated formulation modules consisting of tailor-made, flexible robotic platforms and convenient software, allows for the gamification of research and development.

Christa Nutzhorn, director of business development at Chemspeed Technologies, introduced us to the topic of automated formulation.

Automated formulation, which is the right combination of different ingredients according to formula in an automated way is getting common in the industries of pharma and personal care. In food industry it is not yet very prevalent.

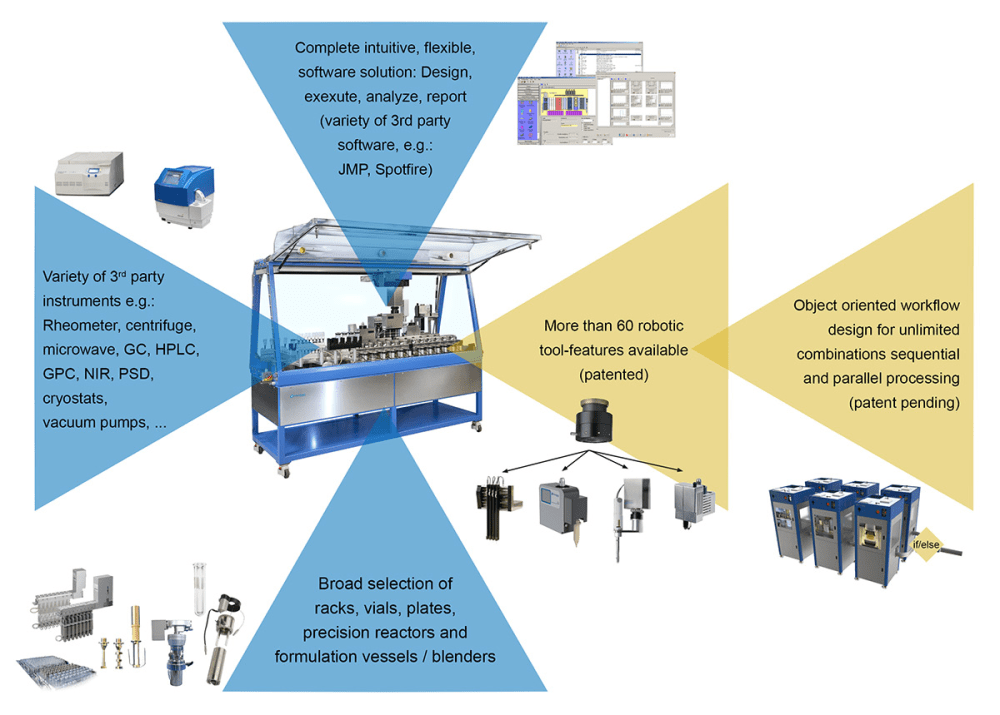

Chemspeed’s systems are tailor-made modules of robotic platforms with innovative tools, where all relevant parameters can be controlled. Therefore, they are highly flexible and adaptable. The compatibility with 3rd party instruments is given as well. The user-friendly software has an intuitive drag and drop functions and you can work with digital twins. The modules are constructed in a space-saving way. Further, as many processes can take part simultaneously the system is time-saving. Every module has cameras and auto-documentation settings where data is collected in real time.

The 4 dimensions of scalable modularity and flexibility (https://www.chemspeed.com)

In the process of automation, the mental attitude of the workers towards the change accounts for 50% of the success. Christa Nutzhorn is calling attention not to underestimate this factor. A positive approach of the users supports a prosperous collaboration between humans and machines, even though some adaption to the system is required by the users.

What about applications in the food industry?

In contrast to Europe, there are already operated partly very big automated formulation installations in the US. Right now, Chemspeed is talking to a company in the swiss food industry, which is an ingredient supplier. Precise, well-documented working in small scales is required in places like that. There are already existing machines for micro-encapsulations and coatings, which could be adapted to processes in the food industry as well. Or for bigger companies where for example precise fine-dosing is needed, automated formulation could be a nice option. Maybe this type of producing is currently not found in the swiss food industry because that level of precision is not needed in many processes, or the throughput is just not that high.

For R&D on the other hand, such flexible automated formulation modules are an excellent option to lower development time, and to get very precise, replicable and well documented outputs. One of the self-constituted objectives of Chemspeed is to speed up Research & Development by offering automated, higher output, cost effective and targeted workflow solutions including tailor-made hardware and software, as well as training and support.

Image Source: https://www.chemspeed.com

Author: Franziska Baeriswyl